REINFORCEKiT® STRUCTURE

REINFORCEKIT STRUCTURE is a tailor-made composite repair system to renovate any kind of corroded structure and restore original integrity, making it even stronger than the original one.

COMPOSITE SOLUTION FOR

STRUCTURAL REPAIR

REINFORCEKiT® STRUCTURE APPLICATIONS

REINFORCEMENT or PROTECTION

(conductor supported platforms, caissons, splash zones, pressure vessels, tanks…)

(bridges, shed structures, beams, columns, roof, walls, decks, sheet piles, jetty piles…)

ENERGY

(windfarms, electrical pylons…)

TRANSPORTATION

(catenary supports, beams, poles…)

Suitable for many others industries…

Uses

- Repair and reinforce structures

- Stop and renovate up to 80% of corrosion

- Restore structures integrity

Applications

- Any structure designs

- Any structure sizes

- Any weather conditions

- Any environments

- Any industries

Benefits

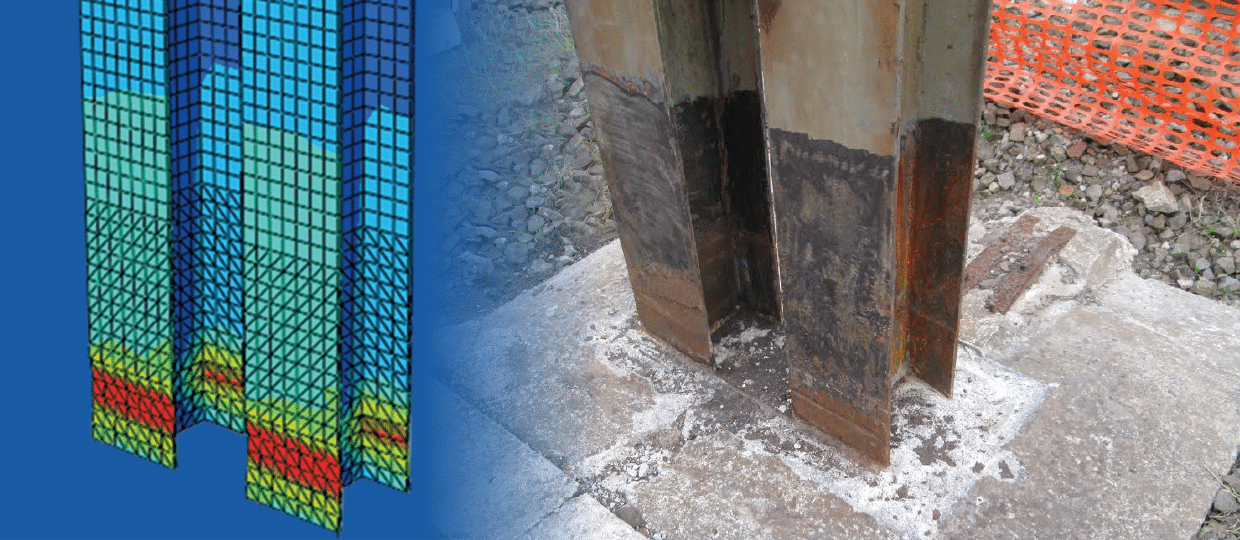

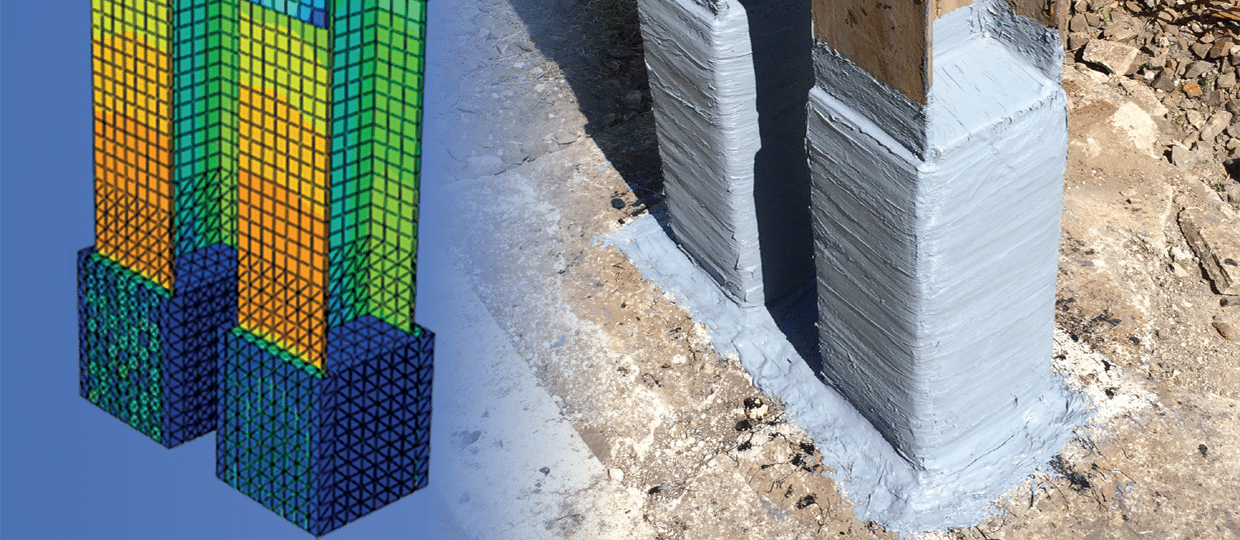

- Tailor-made product for your structure design (Finite Element Analysis)

- Long-term repair (20 years minimum)

- Cost-effective (structure replacement avoided)

- Live repair, no impact on production or traffic

FOCUS ON RAILWAY SECTOR

Specific solutions were co-developed and are commonly used by the French National Railway Company to reinforce their catenary supports. Since 2010, thousands of structures have been protected and repaired successfully thanks to DKiT® and REINFORCEKiT® BEAM patented products.

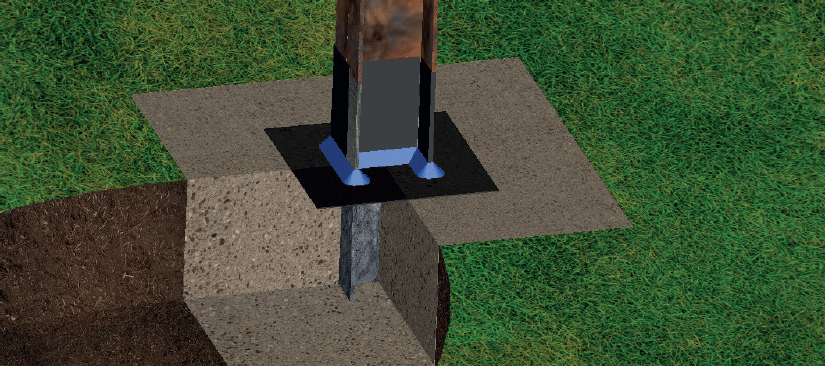

REINFORCEKiT® BEAM CONCEPT

Before

After

IMPLEMENTATION STEPS

Surface preparation

Sa2½ / St3 & roughness

Rz > 60 μm (2.4 mil)

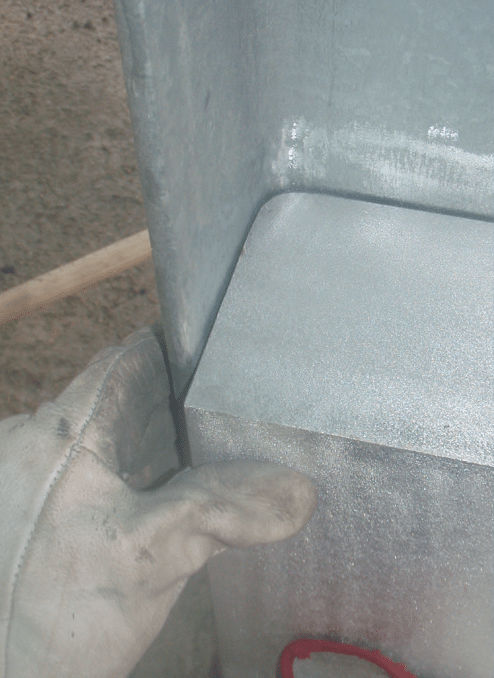

Metal inserts preparation

Metal inserts

application

Kevlar® and epoxy

resin wrapping

Impact &

UV protection

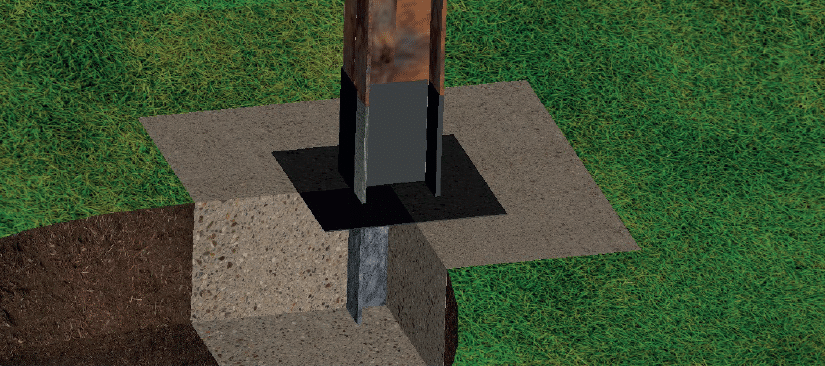

DKiT®

DKiT® is a long-term protection system to prevent corrosion issues and climatic aggressions on any type of structures.

This product is a combination of 3 high-performance coatings. Each layer of coating has one specific action and added together they will offer an excellent protection to increase structure sustainability.

Initially, DKiT® has been co-developed in partnership with the French National Railway Company (SNCF) for railway industry to protect catenary supports (HEA beams) but this product is suitable for any structure designs (poles, beams, deck structures and platings), new or old, without size limitation.

DKiT® COMPOSITION

ANTI-CORROSION

RESIN

WATERPROOFING

FILLER

ANTI-UV AND IMPACT

PROTECTIVE COATING

- Anti-corrosion resin (high-bonding epoxy resin for steel and concrete surfaces)

- Waterproofing filler (elastomeric filler allowing water drainage)

- Anti-UV & impact protective coating (specific coating allowing excellent protection against deterioration and climatic variations)

Uses

- Avoid corrosion and water infiltration between the support and the structure

- Ensure structures integrity and sustainability

- Protect from climatic aggressions, UV and impacts

Applications

- All beam designs

- All structure designs built in concrete

- Old and new installations

Benefits

- Installation without stopping traffic or production

- Complex maintenance avoided

- Cost-effective installation

- Fast and easy application

IMPLEMENTATION STEPS

Surface preparation Sa2½ / St3 &

roughness Rz > 60 μm (2.4 mil)

Epoxy resin application

for corrosion protection

Waterproofing by elastomeric

filler application

Protective coating

application