REINFORCEKiT® 1D

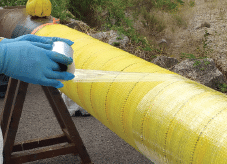

REINFORCEKiT® 1D (R1D) is a water activated prepreg protective system wrapped around the pipe. This technology is a composite Abrasion Resistant Overcoat (ARO) made of fiberglass tape and polyurethane resin.

ABRASION RESISTANT OVERCOAT (ARO)

FOR PIPE PROTECTION

REINFORCEKiT® 1D is an advanced protective overcoat system designed for the robust protection of pipeline coatings during mechanical stresses and scarring associated with trenchless pipeline installation methods, such as Horizontal Directional Drilling (HDD), thrust boring, and micro-tunneling. REINFORCEKiT® 1D effectively serves as an Abrasion Resistant Overcoat (ARO), providing a sacrificial outer layer that shields pre-approved anticorrosion field joint coatings and mainline coatings, such as FBE, 3LPE, 3LPP, shrink sleeves, and other protective tapes, from damage during installation.

REINFORCEKiT® 1D is recommended for use in environments where pipelines are subject to temperatures between -50°C (-58°F) and +150°C (+302°F), providing reliable protection during trenchless installation and preventing costly repairs post-installation.

It can be applied directly over existing pipe coating, requiring no calculations and ready for immediate use.

Onshore / Offshore Topside

Coated pipe protection

Impact protection

External corrosion prevention

Abrasion protection

Uses

- Protective overcoat for pipelines

- Impact and abrasion protection

- External corrosion prevention

Applications

- Onshore and Offshore installations

- All pipe diameters (no limitation)

- All pipe geometries

- Compatible with most common fluid and gas

- Temperature from -50°C to +150°C

Benefits

- Ensure future pipeline integrity

- Cost-effective (2 layers recommended for optimal protection)

- No environmental hazards

- Easy and fast application (fiber already impregnated with resin)

| Use | PIPE PROTECTION & REINFORCEMENT |

| Pipe diameter | No limitation |

| Application temperature | From -50°C to +150°C |

R1D wrapping (spray water continuously)

Compression film application

Compression film perforation

Remove compression film after full curing