Technology at 3X:

Advancing Composite Repair Solutions

At 3X, we specialize in the composite repair of damaged and corroded structures, utilizing advanced epoxy resin formulations and high-performance aramid fiber reinforcements. Our expertise in material science, extensive testing, and cutting-edge Finite Element Analysis (FEA) enables us to design and optimize durable, efficient, and cost-effective repair solutions.

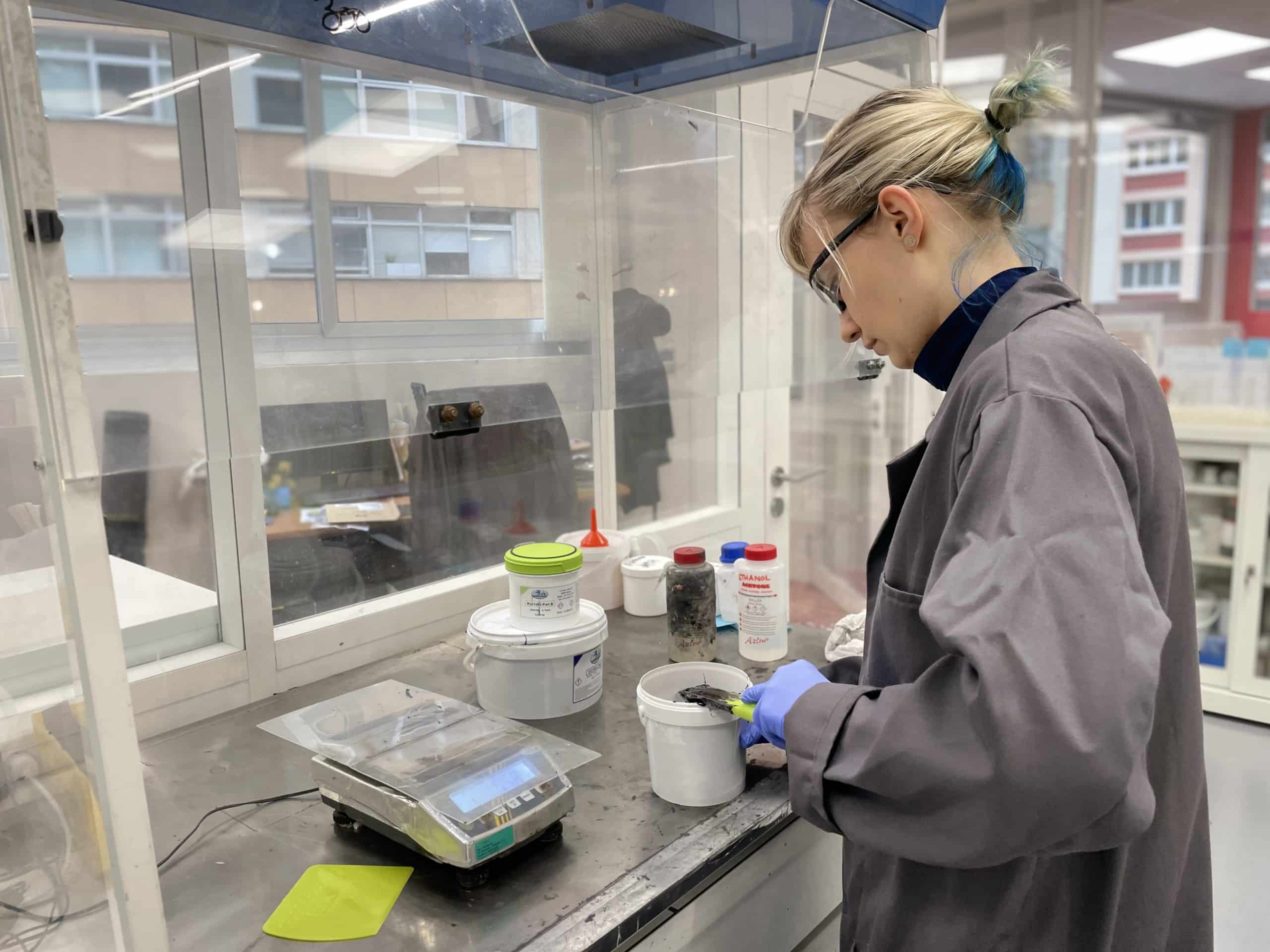

Epoxy Resin Formulation

At 3X, we are experts in epoxy resin formulation, developing advanced solutions tailored to withstand the most demanding environments. Our formulations are engineered to provide optimal adhesion, mechanical strength, and durability in extreme conditions. Whether for subsea applications, where resins must cure underwater and resist long-term exposure to saltwater, or high-temperature environments, where heat resistance is critical, we create customized solutions that ensure superior performance. Our expertise also extends to humid conditions, low-temperature applications, and chemical-resistant formulations, guaranteeing reliability in every scenario.

While REACH compliance is a challenge due to the complexity of high-performance resin formulations, we make every effort to align with regulatory requirements and prioritize environmentally friendly solutions. As part of our commitment to sustainability, we explore alternative resin chemistries that reduce VOC emissions and improve long-term durability. This adaptability allows us to offer tailor-made solutions that meet evolving regulatory and operational requirements. Through continuous innovation, we push the boundaries of composite repair technology, delivering high-performance resins that excel in harsh operating conditions.

Resin Characterization & Quality Control

To ensure reliability and performance, we conduct extensive resin characterization tests, including pot life and polymerization monitoring to evaluate the working time and curing profile at different temperatures. Rheology and viscosity measurements ensure proper flow and impregnation of the reinforcement fibers. Quality control testing establishes a material identity card for incoming raw materials.

Fiber Selection & Composite Manufacturing

Choosing the right fiber reinforcement is essential for optimal mechanical performance. Key parameters include fiber type, such as aramid, carbon, or glass fibers, selected based on required strength, flexibility, and durability. Weave patterns, including plain, twill, or unidirectional weaves, enhance specific mechanical properties. Fabric weight and thickness are adjusted to balance flexibility and strength in repair applications.

Composite Testing & Performance Validation

Our composite materials undergo rigorous testing to validate their structural integrity and performance. Mechanical testing assesses tensile, flexural, compressive, and shear strength to ensure structural reliability. Chemical resistance testing evaluates composite resistance to harsh chemicals and environmental exposure. Cathodic disbondment resistance ensures adhesion and long-term durability in cathodically protected environments. Aging and fatigue testing assess long-term performance through cyclic loading on test specimens and full-scale pipes.

Composite Repair Solutions & Standards

At, we design composite repairs in compliance for pipes and pipings with ISO 24817 and ASME PCC-2, ensuring structural integrity and long-term performance. Our intelligent calculation tool “REA” optimizes material selection and repair dimensioning for the best technical and economic balance while automating material estimation, traceability, and reporting for efficient execution. To ensure safety and compliance, we provide access to Safety Data Sheets (SDS) and detailed application procedures, guiding proper handling and installation.

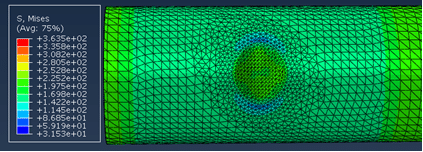

Finite Element Analysis (FEA) for Optimized Repair Design

The extensive data collected from testing feeds into our FEA models, allowing us to precisely dimension repairs by determining the number of reinforcement plies, material selection, and axial repair length while maintaining safety factors. Through detailed stress analysis, we evaluate the metallic substrate to ensure it can sustain operational loads after repair. At the metal-composite interface, we assess adhesion strength and load transfer to prevent delamination or premature failure. Within the composite structure, we apply advanced failure criteria, such as Tsai-Hill and Tsai-Wu, to predict performance under various loading conditions.

Our expertise in FEA enables us to optimize reinforcement placement, minimize stress concentrations, and ensure long-term durability, even in extreme conditions. By integrating real-world test data into our simulations, we refine our designs to provide the most effective and lightweight repair solutions while maintaining high safety margins.

Preparing for the Future: Smart Composite Solutions

At 3X, we are continuously innovating to develop intelligent composite systems capable of monitoring structural health by embedding sensors to detect early signs of wear and degradation. Real-time integrity alerts enable predictive maintenance by detecting insufficient residual thickness or other structural issues.

By leveraging advanced materials, rigorous testing, and cutting-edge simulation, 3X ensures the highest reliability and performance for composite repair solutions, preparing for the future of intelligent infrastructure monitoring.