Notre équipe d’experts reconnus et certifiés

est à votre disposition pour vous conseiller

et vous fournir des informations sur nos activités

Contact

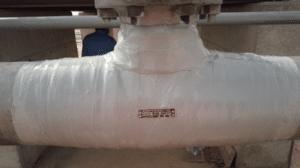

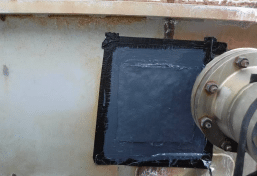

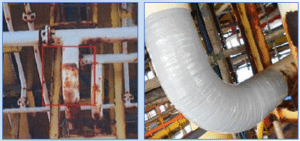

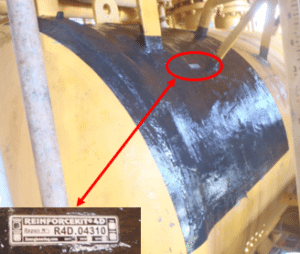

Nous sommes les spécialistes mondiaux

de la réparation avec composites

À propos de nos solutions

À propos de 3X

© 3X Engineering Ekoscan 2025 All rights reserved.