R4D, Pipe subjected to compressive stress – South America

High-performance composite repair solution for pipe reinforcement

Overview

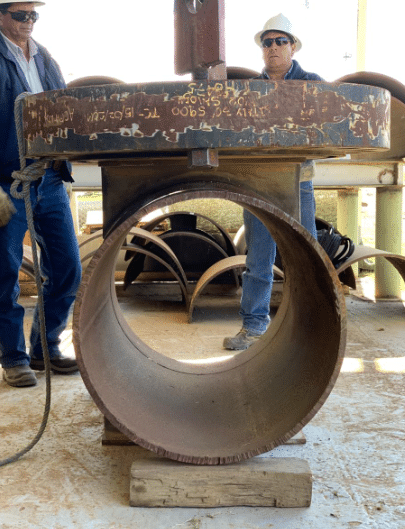

The objective of the job, carried out by 3X local distributor was to reinforce and protect a 30″ pipe subjected to compressive stress in order to verify if the pipe integrity remains preserved once loads are applied.

Results

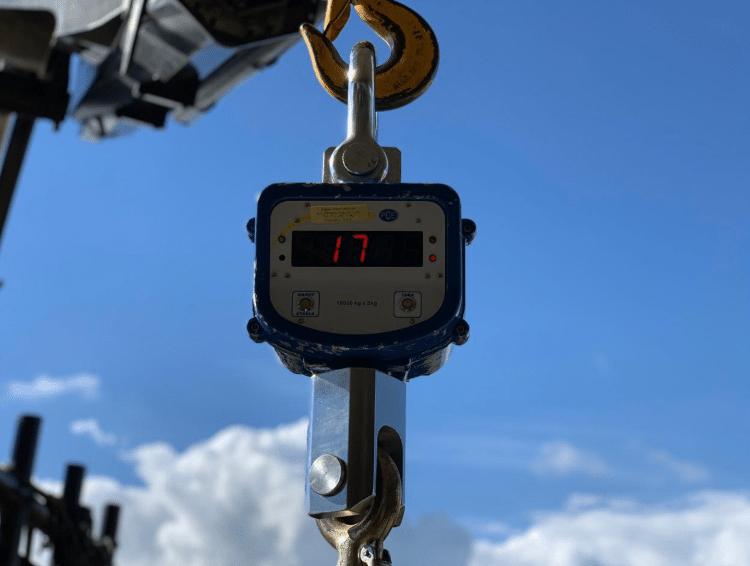

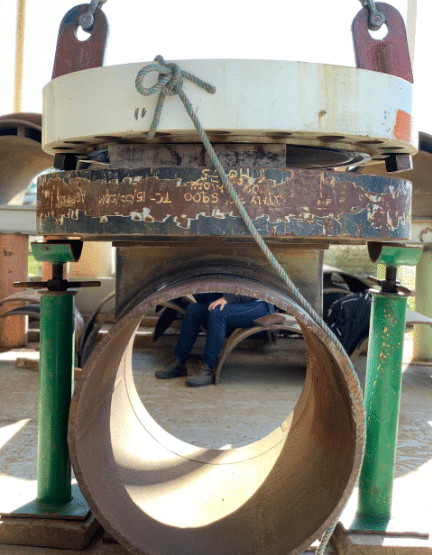

The pipe reinforced with REINFORCEKiT® 4D was subjected to 3.5 tons of external loads without presenting any type of damage or deformation. The lifetime of this composite reinforcement is 20 years.

Defect type |

Pipe subjected to compressive stress |

Details |

30” pipe – Operating temperature 45°C - Pressure 600 psi |

Location |

SOUTH AMERICA |

3X Product type |

REINFORCEKiT® 4D (R4D) |

SCOPE OF WORK

Each reinforcement is designed specifically according to the characteristics of the pipe, the operating conditions and the size of the defect. In accordance with ASME PCC-2 standard and 3X repair calculations, 4 layers of REINFORCEKiT® 4D were determined to reinforce the pipe.

- Before the repair, qualified staff or 3X local distributor inspected and delimited the area to be reinforced.

- Surface preparation was carried out by an external contractor using manual-mechanical tools to obtain a good surface roughness (between 60 and 100 µm) and thus guarantee the bonding between the steel pipe and the composite.

- The surface was cleaned with ethanol and the hygrometric conditions were checked before wrapping process.

- Wrapping composite reinforcement covering the delimited area was completed using Kevlar® tape impregnated with 3X resin (4 layers with a specific repair length according to the characteristics of the loads to which the 30″ pipe would be subjected).

- Once wrapping completed, the inner diameter was measured in order to detect any final deformation.

- Finally, two external loads (1.75 tons each one) were applied to check the resistance of the pipe.