R4D, corrosion – Africa

High-performance composite repair solution for pipe reinforcement

Overview

The objective of the job, performed by 3X ENGINEERING (3X) and its local distributor, was to protect a 16” pipe from aggressive environment on several long sections (for a total of 70-meter length).

Results

Initially developed for subsea application, BOBIPREG® machine is proving to be also very efficient in this onshore configuration. This application method added to onsite conditions offer many benefits:

- easier logistic & safer environment (implementation environment performed in a yard rather than a platform).

- efficiency increased & cost effective (the wrapping was performed four times faster than with traditional method).

Defect type |

Corrosion |

Details |

16” water line |

Location |

AFRICA |

3X Product type |

REINFORCEKiT® 4D using BOBiPREG® |

SCOPE OF WORK

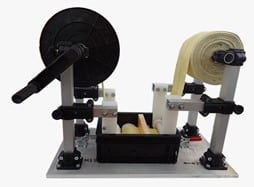

The reinforced protection was performed in a yard, prior on-site assembly, using BOBiPREG® machine. This specific machine, designed by 3X, allows a quick and regular impregnation of the Kevlar® tape with the resin before application.

This pre-preg system was very convenient for this case because the REINFORCEKiT® 4D application should be carried out as fast as possible. The reinforced protection was performed following 4 stages:

- Surface preparation of the pipe using sandblasting to get at least 60 µm roughness and thus ensure a good bonding between the pipe and the composite.

- Kevlar® tape impregnated with R3X1060 resin using BOBIPREG®.

- Wrapping around the pipe using 3X specific resin handles to ensure proper tensile strength during application. This device will facilitate and speed-up the wrapping step. Four layers were applied to guarantee an optimal protection.

- Finalization of the protection with reference plate positioning for traceability purpose.